ViSCO's originally developed software image processing inspection system “Vision Manager”, is included in hardware.

Features high-precision image processing technology, high-speed processing, and an inspection algorithm that rivals human capabilities.

Easy to operate using virtually intuitive control and achieves fluent availability.

Achieves high speed processing and high accuracy appearance inspection

Ability to inspect scratch and foreign matter on gradient image

- In images with uneven shading or shadows, it is possible to detect scars or foreign objects. The detection mode can be selected based on the direction of scars, foreign objects, and gradient differences.

Identifies deformities in non-defective objects using DeFinder

- Register multiple templates of high-quality products to identify statistically correct ones. Achieve high accuracy and stability in detecting defects such as scars, dirt, foreign objects, and other appearance-related flaws.

The ultra-depth camera enables inspections that were previously only achievable through visual examination.

- Capture images from angles that make defects easily visible, utilizing fully focused high-resolution images for achieving precise inspections.

- Black spots or defects inside the hole, highlighted with a red circle, can only be detected using a camera positioned at an oblique angle. It is challenging to identify defects within the inner hole when capturing images from the front or directly above.

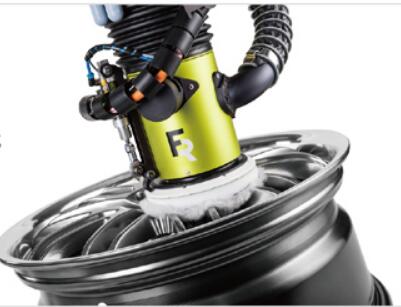

Device Inspection using VTV-9000

Gear appearance inspection

- A robotic arm grips the gear and rotates it, capturing high-resolution images of each tooth surface. This process ensures a high-precision inspection of the side, top, and bottom surfaces.

High-precision inspection

- Appearance and size inspection.

- Identifies defective object with filling failure.

- Component size: < 5mm.

- Inspection accuracy: < 0.01mm.

- Resolution: 0.0017mm.

A:

A: VISCO lens set |

B: Cave-diving material collecting boxes |

C: VISCO light source set |

D: Parts for inspection |

E: Material-dividing air-blowing module

Achieves high speed and high-precision appearance inspection

Achieves high speed and high-precision appearance inspection

A: VISCO lens set | B: Cave-diving material collecting boxes | C: VISCO light source set |

A: VISCO lens set | B: Cave-diving material collecting boxes | C: VISCO light source set |